Hybrid Hydropower Plants

In medium and small hydropower plants, steel sheet piles are often used, which are thermally activated with Naware technologies. Using our energy sheet piles, hydropower plants can build up a cold local heating network to supply nearby residential and commercial areas with regenerative heating and cooling.in Großweil an der Loisach, Bavaria, Germany

Better efficiency, higher yield

In medium and small hydropower plants, steel sheet pile walls are often used, which are thermally activated using Naware technologies.

With our energy sheet pile walls, hydropower plants can set up a cold district heating network to supply nearby residential and commercial areas with regenerative heating and cooling.

Economic efficiency and profit are significantly improved and additional sources of income are opened up. The electricity produced via the hydropower plant is used for the generation of heat. Thus, a local, decentralized and autonomous heat supply is established.

The novel energy sheet pile walls meet all the requirements of precautionary water protection when using climate-friendly geothermal energy in an appropriate manner and with the necessary care. They ensure compliance with all the requirements of the relevant generally recognized rules of technology (e.g. VDI 4640-1, VDI 4640-2 (draft version), DIN 8901) and in some cases exceed them.

Rules and recommendations of the Committee for Waterfront Structures (EAU) are not restricted by energy sheet piles in any way.

How Hybrid hyrdopower Plants Work

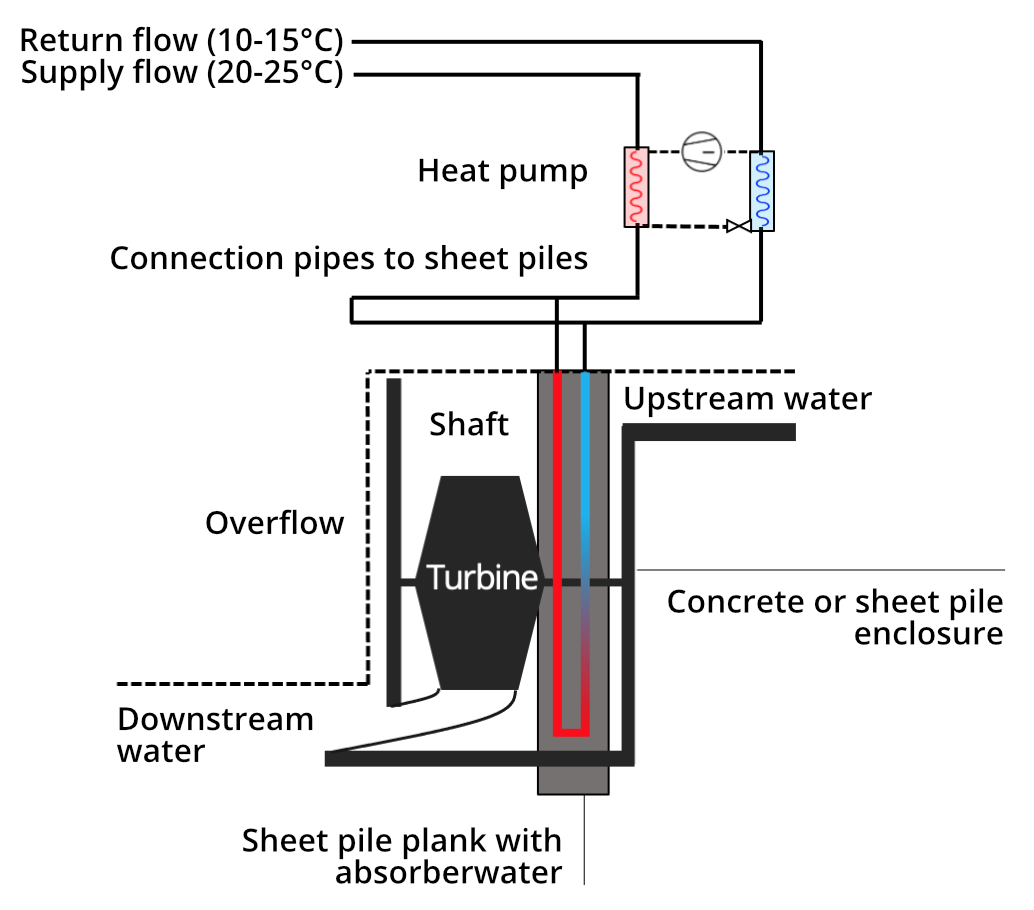

The structure and operating principle of a Hybrid Hydropower Plant (HHPP) is shown above. The photo shows a possible realization, the graphic the schematic structure.

In the shaft power plant, the water first flows from the headwater into the shaft consisting of energy sheet piles, flows through the turbine, which drives a generator, and, after performing work, reaches the tailwater slightly cooled. The shaft and optionally the entire area formed by concrete walls (picture on the right) are made of energy sheet pile walls, which are required as a simple sheet pile wall during construction anyway. The temperature of the water circulating in the heat network and absorber is changed by a heat pump connected between the heat network and the absorber pipes in such a way

- that the return flow from the DG (10...15°C) is cooled to values close to 0°C via the evaporator of the heat pump, thus maximizing the heat input from the river water into the absorber, and

- and the water coming from the energy sheet pile wall and heated to 5...10°C is raised to 20...25°C via the condenser of the heat pump and fed at this temperature into the flow of the DG.

An important advantage of low-temperature networks is that the pipes do not need to be insulated, which saves costs. In the connected buildings there are raising stations in the form of another small heat pump, which raises the temperature from the return of the heating circuit or a buffer tank to the level required in the house according to demand. This results in the second major advantage of cold networks, as it is possible in this way to convert energy-saving houses and existing conventional buildings alike to regenerative district heating.